Metal roofing installation is a popular choice for homeowners due to its durability, low maintenance, and energy efficiency. This guide provides a comprehensive overview of the process, ensuring a smooth and successful project for both DIY enthusiasts and professionals. By following the steps outlined, you can achieve a long-lasting, weather-tight roof that enhances your home’s curb appeal and value.

Overview of Metal Roofing

Metal roofing is a durable, sustainable, and energy-efficient option for homeowners. Known for its longevity, it can last 50 to 70 years, making it a cost-effective choice. Metal roofs are resistant to mold, moss, and organic growth, and they provide excellent weather resistance. Available in various styles, they enhance curb appeal while offering low maintenance and environmental benefits, making them a popular choice for modern homes.

Importance of Proper Installation

Proper installation of a metal roof is crucial for ensuring its durability, weather resistance, and safety. Incorrect techniques can lead to leaks, structural issues, and reduced lifespan. A well-installed metal roof provides a secure, energy-efficient, and low-maintenance solution, protecting your home from harsh weather conditions while maintaining its aesthetic appeal and value over decades.

Benefits of Metal Roofing

Metal roofing offers exceptional durability, low maintenance, and resistance to mold, moss, and weather damage. It provides energy efficiency, reducing heat absorption, and lasts 50-70 years, making it a cost-effective, sustainable choice for homeowners seeking long-term protection and curb appeal.

Advantages Over Traditional Materials

Metal roofing surpasses traditional materials like asphalt shingles with its superior durability, lasting 50-70 years compared to 20-30 years for shingles. It offers excellent resistance to mold, moss, and weather damage, while its reflective properties reduce heat absorption, enhancing energy efficiency. Metal roofs are also low maintenance, requiring only occasional inspections and fastener checks, making them a sustainable and cost-effective choice.

Durability and Longevity

Metal roofs are renowned for their exceptional durability, lasting 50 to 70 years or more, far outperforming traditional materials like asphalt shingles. They resist weathering, moss, and mold, ensuring minimal wear over time. With proper installation, metal roofs require only occasional inspections and fastener tightening, making them a long-lasting, low-maintenance option for homeowners seeking a reliable roofing solution.

Sustainability and Energy Efficiency

Metal roofs are highly sustainable, as most materials are recyclable, reducing environmental impact. They reflect sunlight, lowering energy consumption in summer, and can be coated for enhanced thermal performance. This eco-friendly option not only minimizes heat absorption but also supports energy savings, making it a responsible choice for environmentally conscious homeowners seeking a durable and efficient roofing solution.

Essential Tools and Materials

Key tools include a tape measure, snips, hammer, safety gear, and a sealant gun. Materials like underlayment, fasteners, and weatherproofing components ensure a secure and durable installation.

Tools Required for Installation

Essential tools for metal roofing installation include a tape measure, snips or metal shears, a hammer, screwdrivers, and a drill. Safety equipment like gloves, goggles, and a harness is crucial. A sealant gun for weatherproofing and specialized tools like a panel cutter or crimper may also be needed for precise cuts and secure fastening.

Key Materials Needed

Primary materials include high-quality metal roofing panels, underlayment for moisture protection, and durable fasteners. Flashing is essential for sealing roof edges and valleys, while sealants ensure weather tightness. Additional materials like closure strips and ridge caps are necessary for finishing touches, ensuring a secure and long-lasting installation.

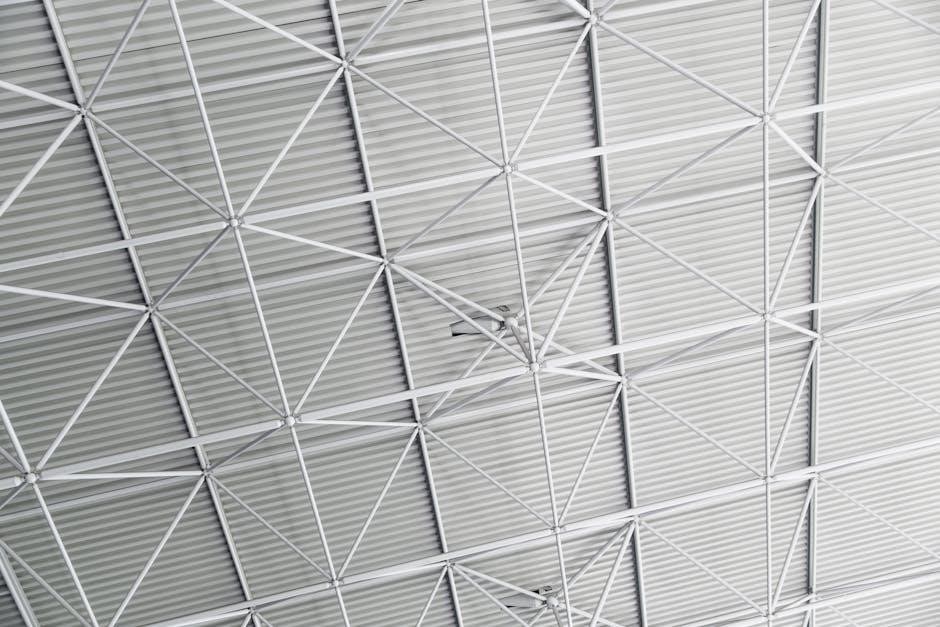

Step-by-Step Installation Process

Begin with surface preparation, ensuring a clean and secure base. Install underlayment for protection, then attach metal panels, followed by flashing and weatherproofing for a durable finish.

Preparation of the Roof Surface

Ensure the roof deck is clean, dry, and free from debris. Inspect for loose or damaged areas and secure them. Check for protruding nails and remove any obstacles. Apply a high-quality underlayment to protect the roof and ensure a smooth surface for metal panel installation. This step is crucial for a durable and weather-tight finish.

Installing Underlayment

Apply a high-quality underlayment material to the entire roof surface, ensuring a smooth and even layer. Use synthetic or asphalt-based underlayment, securing it with fasteners or adhesive. Ensure tight fitting around edges, vents, and roof penetrations. Proper installation prevents moisture damage and provides a stable base for metal panels, enhancing durability and weather resistance.

Mounting Metal Panels

Begin by aligning the first metal panel with the roof edge, ensuring proper overhang. Secure panels using approved fasteners, spaced evenly as per manufacturer guidelines. Tighten screws snugly to avoid overtightening, which can damage the panel. Work from the eave upward, overlapping panels as specified. Ensure panels are square and securely fastened at the ridge and valleys for a durable, weather-tight finish.

Flashing and Weatherproofing

Flashing and weatherproofing are critical steps in metal roofing installation, ensuring water tightness at intersections and edges. Proper installation prevents leaks and enhances durability, safeguarding your home from weather damage.

Types of Flashing

Common types of flashing for metal roofs include sidewall flashing, which protects wall and roof intersections, and valley flashing, designed for areas where two roof slopes meet. Additionally, ridge flashing and eave flashing are used along roof ridges and edges to prevent water infiltration. Each type ensures a watertight seal, tailored to specific roof features and weather conditions.

Ensuring Weather Tightness

To ensure weather tightness, proper sealing of all seams, fasteners, and flashing is essential. Using high-quality sealants and ensuring tight fastener installation prevents leaks. Regular inspections and maintenance help maintain the roof’s integrity, while correct panel alignment during installation minimizes gaps. Adhering to manufacturer guidelines and local building codes further enhances the roof’s ability to withstand harsh weather conditions effectively.

Safety Considerations

Metal roofing installation requires proper safety gear, including gloves, safety glasses, and a harness. Ensure a clean, dry workspace to prevent slips. Always follow manufacturer guidelines and safety protocols to minimize risks and avoid accidents during the installation process.

General Safety Tips

Always wear proper safety gear, including a harness, gloves, and safety glasses. Ensure the workspace is clean and dry to prevent slips. Use ladders cautiously and maintain three-point contact. Never stand on unsecured panels, as they may bend or shift. Follow manufacturer guidelines for tools and materials. Ensure all power tools are in good condition and keep loose clothing tied back. Regularly inspect equipment and ensure proper ventilation. Avoid working in extreme weather conditions, such as heavy rain or strong winds, as this can increase the risk of accidents. Keep a first aid kit nearby and have a plan for emergency situations. Proper training and experience are essential for handling specific hazards, so consider seeking professional help for complex tasks. By adhering to these safety tips, you can minimize risks and ensure a safe installation process.

Handling Specific Hazards

Be cautious of sharp metal edges, which can cause cuts. Wear gloves and use tools to handle panels safely. Avoid power lines and ensure proper grounding to prevent electrical hazards. Use proper ladder safety and secure panels to prevent falls. Always inspect for structural weaknesses before walking on the roof. Keep tools and materials organized to avoid tripping hazards. Never overload roof sections, as this can lead to collapse. Ensure proper ventilation to prevent heat exhaustion. Handle large panels with assistance to avoid strain or dropping. Always follow manufacturer guidelines for specific materials and tools to minimize risks.

Common Mistakes to Avoid

Incorrect measurements and improper cutting of panels can lead to poor fits and leaks. Avoid under-tightening fasteners, as this compromises weatherproofing and structural integrity over time.

Errors in Measurement and Cutting

Inaccurate measurements and improper cutting of metal panels are common mistakes that can lead to poor fits, leaks, and structural weaknesses. Always use precise tools to measure and cut panels, ensuring they align perfectly with the roof’s dimensions. Double-check all measurements before cutting to avoid costly errors and ensure a watertight seal. Proper fitting is essential for durability and performance.

Improper Fastening Techniques

Using incorrect screws or over-tightening fasteners can damage metal panels, leading to leaks and reduced structural integrity. Ensure screws are spaced evenly and driven straight to avoid warping the metal. Under-tightening can result in loose panels, while over-tightening may void warranties. Always follow manufacturer guidelines for screw placement and torque to ensure a secure, weather-tight seal and maintain the roof’s longevity and performance.

Maintenance and Repair

Regular inspection ensures longevity, while cleaning debris and tightening fasteners prevent leaks and damage. Addressing issues promptly maintains the roof’s integrity and performance over time effectively.

Regular Inspection Practices

Regular inspections are crucial for maintaining metal roofing integrity. Check for loose fasteners, rust, or damage during seasonal changes. Inspect panels, flashings, and seams for gaps or wear. Clean debris from surfaces and gutters to prevent water accumulation. Address minor issues promptly to avoid costly repairs. Schedule professional inspections annually or after severe weather events for optimal performance and longevity.

Factors Affecting Cost

The cost of metal roofing installation depends on material quality, labor expenses, and project complexity. Additional factors include permits, underlayment, and specialized tools, influencing the total budget.

Material and Labor Costs

Metal roofing installation costs are primarily driven by materials and labor. High-quality metal panels, underlayment, and flashing are key material expenses. Labor costs vary based on the installer’s expertise, roof size, and complexity. Additional factors include permits, fasteners, and specialized tools, all contributing to the overall budget. These expenses ensure a durable and weather-tight installation, offering long-term savings through reduced maintenance and energy efficiency.

Permits and Additional Expenses

Obtaining necessary permits is crucial for compliance with local building codes, adding to the overall cost. Additional expenses include inspections, potential upgrades to meet code requirements, and disposal fees for old roofing materials. These factors, while often overlooked, are essential for a legally compliant and safely executed metal roofing installation, impacting the total budget accordingly.

DIY vs Professional Installation

DIY metal roofing offers cost savings and control but demands precision and safety precautions. Professional installation ensures expertise, warranties, and compliance, though at a higher upfront cost.

Pros and Cons of DIY

DIY metal roofing offers cost savings and control over the project timeline. It suits homeowners with experience in roofing or handyman skills. However, improper installation risks weather tightness and durability. DIY requires purchasing tools and materials, ensuring safety measures, and adhering to local building codes. While it can be rewarding, it demands precision and time, making it less ideal for large or complex roofs.

When to Hire a Professional

Hiring a professional is advisable for complex roof designs, large-scale projects, or when lacking DIY experience. Experts ensure compliance with local codes, optimal weatherproofing, and warranties. They handle specialized tools and materials, minimizing errors and ensuring longevity. Professionals also offer liability insurance and guarantees, providing peace of mind for a flawless, long-lasting metal roofing installation.

Metal roofing installation offers a durable, low-maintenance, and energy-efficient solution for homeowners. With proper planning and execution, it enhances your home’s curb appeal and value significantly.

Final Thoughts

Metal roofing installation is a rewarding project that combines durability, sustainability, and aesthetic appeal. By following a detailed guide, homeowners can ensure a successful outcome, enjoying long-term benefits like energy savings and minimal maintenance. Whether tackling it yourself or hiring a professional, the end result is a high-quality roof that enhances your home’s value and curb appeal for decades.

Encouragement to Proceed

Embarking on a metal roofing installation project is a wise decision, offering lasting benefits like durability and energy efficiency. With a detailed guide, you’ll navigate the process confidently, whether DIY or professional. Take the first step toward enhancing your home’s protection and appeal, knowing the effort will yield a rewarding, long-term investment in your property’s value and functionality.